charpy impact test sheet metal|charpy impact cheat sheet : mail order The Charpy impact test, performed according to EN ISO 148-1, involves the use of a pendulum hammer that strikes a notched metal specimen. The specimen is placed on . WEB27 de nov. de 2023 · Reflects the activity of making clean the forum. Threads. 9. Messages. 10. 3D movies free download plz. Dec 10, 2023. Captain. Welcome to Warez-BB site World #1 Forum, Login on your Warez BB Forum without Alternative or Replacement.

{plog:ftitle_list}

WEBA Polícia Civil de São Paulo investiga o abandono de uma recém-nascida ainda com o cordão umbilical dentro de um saco plástico na frente de uma casa no Parque Edu .

The ISO 148-1 standard specifies the Charpy (U-notch and V-notch) impact test on metals for determination of the impact strength. The impact strength of a material is an important .The Charpy impact test provides characteristic values for the impact .In this investigation, we performed instrumented Charpy tests in order to characterize the impact properties of three steels, used by NIST for the production of Charpy reference specimens .

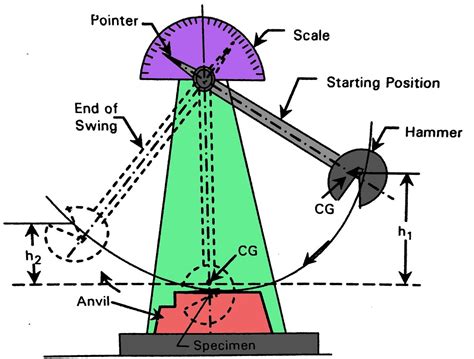

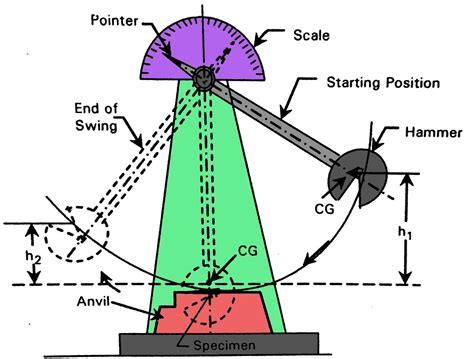

The Charpy impact test, performed according to EN ISO 148-1, involves the use of a pendulum hammer that strikes a notched metal specimen. The specimen is placed on .

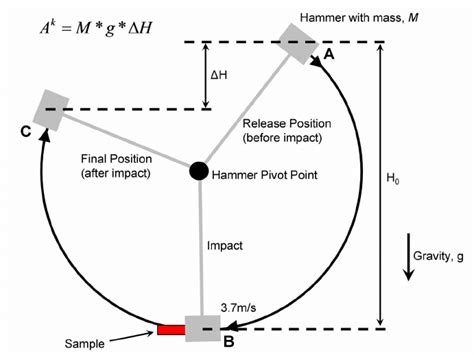

Charpy impact testing is a method used to determine the toughness or impact resistance of materials, particularly metals. It measures the amount of energy absorbed by a material during fracture, providing valuable insight into its .The Charpy impact test provides characteristic values for the impact strength at high strain rates in the form of a surface area related value. The test measures the impact energy in relation to the fracture surface in joules. Charpy impact testing, or V-notch testing, is an evaluation of a material’s strength and performance under impact conditions. It involves a pendulum with a pointed hammer on the end swinging and hitting a machined .

The Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain-rate test that determines the amount of energy absorbed by a material during fracture. This .In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a . The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures! Test setup and test procedure In the Charpy impact test, a notched specimen is .Many notched bar impact tests of different designs and loading have been used to predict brittle fracture of ferritic steels. In the USA, the Charpy specimen has been standardized in ASTM E23 for impact three-point bend testing (ASTM E23 1999).Figure 1 illustrates a standard ASTM type A Charpy impact test specimen. The Charpy three-point bend specimen is more convenient .

Charpy impact testing (also known as the Charpy v-notch test) is a high strain rate testing standard that determines the amount of energy absorbed by a material during a fault (Kim et al., 2015).

charpy impact testing procedure

The Charpy impact test is performed to evaluate the resistance of the metal to breakage by flexural shock or impact load according to standard test method ASTM D6110. Fig 1: Charpy Test Apparatus This test determines the amount of .The ASTM E23 standard describes notched bar impact testing of metals according to Charpy and Izod.For the test, a notched metal specimen is broken in half using a pendulum hammer. The ASTM E23 standard describes the requirements for specimens, for the performance of the test, for result reports and for testing machines, i.e., pendulum impact testers at ambient .

refractometer for chlorides

The Charpy impact test is one of the most widely used techniques for evaluating the impact toughness of metallic materials. This test is based on measuring the energy absorbed by a material during fracture caused by a sudden impact, simulating real stress conditions that could cause a metal component to fracture. Charpy impact testing determines the impact energy of materials. The test procedure, the application of charpy testing, factors affecting impact energy, the ductile to brittle transition are all covered. Basic principle and practical procedure of the Charpy impact test - Testing machine, test specimen - Basic principle, impact energy measurement - Temperat.

The Charpy impact test, also commonly referred to as the Charpy V-notch test by material scientists, serves as a standardized high-strain rate examination to quantify the energy absorbed by a material upon fracture. The absorbed energy functions as an indicator of the material’s notch toughness. 1.1 These test methods describe notched-bar impact testing of metallic materials by the Charpy (simple-beam) test and the Izod (cantilever-beam) test. They give the requirements for: test specimens, test procedures, test reports, test machines (see Annex A1) verifying Charpy impact machines (see Annex A2), optional test specimen configurations .The Charpy impact test measures the impact energy absorbed by a metal sample when struck. This test helps determine the toughness and notch sensitivity of . This test helps determine the toughness and notch sensitivity of metals used in sheet metal fabrication. Go Back. View Glossary. Taichung City, Taiwan; View E-mail +886-4-2350-0999; Get .

charpy impact testing methods

“JR” indicates the quality grade related to Charpy impact test energy value ≥ 27 J at room temperature (20 °C); “C” indicates the material is suitable for cold flanging, cold bending, cold forming or cold drawing, e.g. S235JRC (1.0122). 1.0038 is the designation of steel number. S235JR steel general delivery conditions are as follows:Is there a method and a standard impact test specimen prepared with a metal sheet/plate, instead of metal bars such as used at Charpy impact test?

Charpy Test The Charpy test is a good way to measure material toughness. It is useful for materials that exceed the 10.mm (0.394.inches) Charpy height. Specimens can also be made in ¾, and ½ sizes so in theory a 0.20 inch thick specimen can be produced. The Charpy specimen is relatively easy to make and test.This page introduces the Charpy impact test principle and methods; as well as evaluation methods, test piece standards, differences from the Izod impact strength test, and methods for measurement of the fracture surface. The 3D Solutions Library operated by KEYENCE introduces examples of shape measurement problems and the latest solutions for various industries, .

The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures! Test setup and test procedure. In the Charpy impact test, a notched specimen is .

According to current Charpy test standards (ASTM E23-12c and ISO 148-1:2009), absorbed energy (KV) results from partially fractured test specimens can be averaged with the results from fully fractured specimens. However, most researchers agree that if a specimen does not fully fracture at the end of a Charpy test, a significant Our discussion will cover the different types of impact testing, the necessary equipment, and the valuable data these tests provide. Impact Testing – Charpy and Izod Tests. The impact testing method is pivotal for .

impact testing of mild steel, the Charpy Impact Test can provide information on how much energy a specimen such as mild steel can absorb under an impact scenario. In this context, the following sections will present information on: 1) impact testing; 2) effect of . The Charpy impact test, just like any impact testing method, determines the toughness of materials by measuring the amount of energy absorbed by a specimen as it fractures while being struck by a .

An impact test consists of a striker hitting the test specimen to transfer a large force in a short time.You can use a drop tower or a pendulum tester to achieve such large forces.. A striker is dropped vertically from a height for a drop tower test and uses gravity to achieve the necessary impact energy. Similarly, in a pendulum test, the striker is fixed to an arm that swings like a .

charpy impact test sample

Charpy Testing for Your Steel Products. The Charpy impact test method, also known as the Charpy V-notch test, will determine the impact strength and toughness of carbon steel products. It does this by measuring the amount of energy absorbed by a pendulum tool, with more brittle metals breaking more easily than “tougher” metals.Charpy Impact Test Standards . • What is the effect of temperature on the fracture of metal? Structural Metals Lab 1.3 53:086 – Spring 2008 The University of Iowa 17 53:086 Civil Engineering Materials Charpy Worksheet Group:_____ Date:_____ 1018 CR Steel Group† Fracture Energy, J T 1 =-78.5 .

V-notch Charpy impact test has been widely used to qualify toughness of steels and welds (e.g., [5, 6]). In this work, instrumented Charpy tests of pre-charged steel specimens were conducted at ambient temperature using a pendulum machine with a capacity of 750 J. Two to three repetitive specimens were tested for each pre-charging condition.Charpy test. Metal Supermarkets. World's largest small-quantity metal supplier. 100+ brick-and-mortar stores. . Expanded Sheet. 3003. Flat Bar. 6061; 6063; 7075. Hexagon Bar. 6061. Perforated. 3003. Pipe. 6061; 6063. Plate. 2024; 3003; 5052; 6061; 7075. Rect. Tube. . A pendulum-type single-blow impact test (also known as the Charpy V-notch .

The Charpy impact test is still used throughout sectors to assess material toughness, from construction and manufacturing to engineering and beyond. This test offers practical insights into how materials respond to sudden, dynamic impacts. Even as businesses change, the Charpy impact test is still a valuable and essential tool.

The Charpy test is used to determine the resistance capacity of metal (steel) specimens against the sudden impact of a pendulum that swung from a certain height. The Charpy impact is also known as the Charpy V-notch test because the specimen used in this test is cut at a certain depth in a ‘V’ [.]DOI: 10.1016/j.ijmecsci.2020.105627 Corpus ID: 216511752; Determination of Johnson–Cook parameters and evaluation of Charpy impact test performance for X80 pipeline steel @article{Cao2020DeterminationOJ, title={Determination of Johnson–Cook parameters and evaluation of Charpy impact test performance for X80 pipeline steel}, author={Yuguang Cao .

refractometer for citrus

refractometer for cnc coolant with good resolution

WEBÉ uma funcionalidade desenvolvida para verificar a proximidade entre um anunciante e um visitante. Assim, um visitante poderá visualizar os perfis de anunciantes que estiverem .

charpy impact test sheet metal|charpy impact cheat sheet